Hoʻokuʻu i ka polyvinyl chloride resin

Hoʻokuʻu ʻia ka polyvinyl chloride resin,

PVC SG5, PVC SG6, PVC SG8,

Hoʻokuʻu i ka polyvinyl chloride resin

SG-1: K waiwai 77-75 awelika degere o ka polymerization

SG-2: K waiwai 74-73 awelika degere o ka polymerization

SG-3: K waiwai 72-71 awelika degere o ka polymerization 1350-1250

SG-4: K waiwai 70-69 awelika degere polymerization 1250-1150

SG-5: K waiwai 68-66 Awelika polymerization degere 1100-1000

SG-6: K waiwai 65-63 Awelika polymerization degere 950-850

SG-7: K waiwai 62-60 awelika polymerization degere 850-750

SG-8: K waiwai 59-55 Awelika polymerization degere 750-650

Hoʻohana nui:

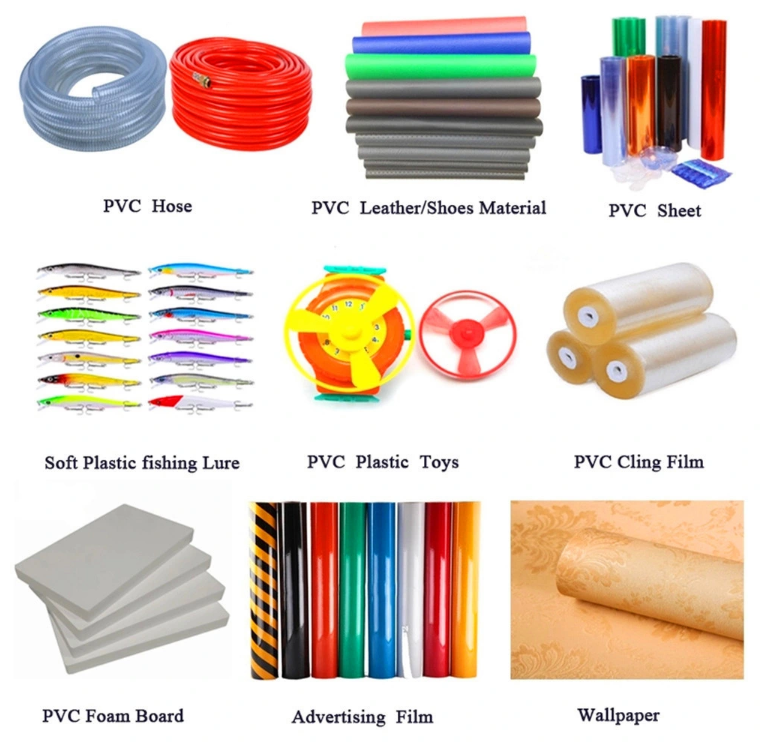

Hiki ke hana ʻia ka resin PVC i nā ʻano mea like ʻole, e like me kona hoʻohana ʻana i hiki ke hoʻokaʻawale ʻia i nā huahana palupalu a paʻakikī i ʻelua mau ʻāpana, i hoʻohana nui ʻia i ka hana ʻana i nā pepa aniani, nā paipu paipu, nā kāleka gula, nā mea hoʻokahe koko, palupalu, paipu paʻakikī. , nā papa, nā puka a me nā Windows, nā profiles, nā kiʻiʻoniʻoni, nā mea hoʻoheheʻe uila, nā kaula kaula, nā mea hoʻokahe koko a pēlā aku.

1.PVC maʻamau nā mea palupalu a paʻakikī - hiki ke hoʻohana ʻia ka extruder i loko o nā paipu palupalu a paʻakikī, nā kaula, nā uea, a me nā mea ʻē aʻe; a me nā mea e pono ai i kēlā me kēia lā a me nā kaʻa a me nā lako uila.

2.PVC paʻa paipu a me ka profile - i hoʻohālikelike ʻia me nā plastics ʻē aʻe, ʻoi aku ka maikaʻi o ka pale ʻana i ka wā kahiko, ka ikaika o ka hopena kiʻekiʻe a me ka paʻakikī, ke kumu kūʻai haʻahaʻa, kūpono no nā paipu hoʻoheheʻe a me nā paipu hale ʻē aʻe, a me nā profile profile.

3.PVC kiʻiʻoniʻoni - PVC a me nā mea hoʻohui i hui pū ʻia, plasticized, me ka hoʻohana ʻana i ʻekolu a ʻehā paha roller calendering mechanism i loko o kahi mānoanoa kikoʻī o ke aniani a i ʻole ke kala kala, me kēia ʻano hana kiʻiʻoniʻoni, lilo i calendering film. Hiki nō hoʻi ke ʻoki ʻia, nā ʻeke ʻeke wela, raincoats, tablecloths, pale, inflatable toys, etc.Wide transparent film hiki ke hoʻohana 'ia no greenhouses, plastic greenhouses a me ka plastic mulch.Bidirectionally kikoo kiʻiʻoniʻoni, ka wela shrinkage waiwai, hiki ke hoʻohana 'ia no ka shrink packaging.

4.PVC uhi nā huahana - backed artificial ʻili he PVC i hui ʻia ma ka lole a i ʻole ka pepa, a laila plasticized ma mua o 100 degrees Celsius.PVC a me nā mea hoʻohui hiki ke ʻōwili ʻia i loko o kahi kiʻiʻoniʻoni, a laila kaomi pū me ka substrate.The artificial ili me ka ʻole 'Oloka'a pololei 'ia ka substrate e ka kalena i loko o kekahi mānoanoa o ka pepa palupalu, a laila kaomi 'ana ma ke kumu. Hiki ke ho'ohana 'ia ka 'ili artificial e hana i nā 'eke, 'eke, nā uhi puke, nā sofas a me nā cushions ka'a, a me ka 'ili papahele, i ho'ohana 'ia e like me ka papahele. no na hale.

5.PVC hu'ahu'a huahana - palupalu PVC hui 'ana, e ho'ohui i ka nui pono o ka hu'ahu'a 'ana e hana pepa mea, hu'ahu'a no ka hu'ahu'a plastic, hiki ke ho'ohana 'ia e like me ka hu'ahu'a pa'ipa'i, kamaa, insole, a me ka ha'iha'i-ho'opa'a pa'a pahu mea. extruder i hoʻokumu ʻia i loko o ka pā PVC paʻakikī haʻahaʻa haʻahaʻa a me ka profile, hiki ke pani i ka hoʻāʻo lāʻau, he ʻano mea hale hou.

6.PVC transparent pepa - PVC me ka hopena hoʻololi a me ka stabilizer, ma hope o ka hui 'ana, plasticizing, calendering a lilo i akaka pepa. Thermoforming hiki ke hana i loko o ka paia lahilahi ipu malamalama a hoʻohana 'ia no ka vacuum blister packaging.He mea hoʻopili maikaʻi loa ia a me nā mea hoʻonaninani.

7 PVC paʻa pāpaʻi a me ka pā - PVC hoʻohui i ka stabilizer, lubricant a me ka filler, ma hope o ka hui ʻana, hiki i ka extruder ke hoʻokuʻu i nā ʻano like ʻole o ka paipu paʻakikī, ka paipu ʻano, ka bellows, hoʻohana ʻia e like me ka paipu iho, ka paipu wai, ka lima uea a i ʻole ke alapiʻi lima. hiki ke hana i ka mānoanoa like ʻole ma ke kaomi wela i nā ʻāpana laminated. Hiki ke ʻoki ʻia ka pepa i ke ʻano i makemake ʻia, a laila hoʻohana ʻia ke koʻokoʻo kuʻi PVC e hoʻopaʻa ʻia i loko o nā ʻano o nā pahu hoʻopaʻa ʻana i ka corrosion kemika, nā ea a me nā ipu me ka ea wela.

8.PVC 'ē aʻe - ua 'ākoakoa nā puka a me nā puka makani me nā mea hana kūikawā paʻakikī. I kekahi mau ʻāina, ua noho ʻo ia i ka mākeke o nā puka a me nā puka makani me nā puka lāʻau a me nā puka makani alumini; ); ipu hakahaka.

Nā kikoʻī huahana

ʻO PVC kahi acronym no ka polyvinyl chloride.ʻO ka resin kahi mea i hoʻohana pinepine ʻia i ka hana ʻana i nā plastics a me nā rubbers.ʻO ka resin PVC kahi pauka keʻokeʻo i hoʻohana mau ʻia e hana i nā thermoplastics.He mea synthetic ia i hoʻohana nui ʻia i ka honua i kēia lā.ʻO ka polyvinyl chloride resin he mau hiʻohiʻona koʻikoʻi e like me ka nui o nā mea maka, ka ʻenehana hana makua, ke kumu kūʻai haʻahaʻa, a me ka nui o nā hoʻohana.He mea maʻalahi ka hana a hiki ke hana ʻia e ka hoʻoheheʻe ʻana, laminating, injection molding, extrusion, calendering, blow molding a me nā ʻano hana ʻē aʻe.Me nā waiwai kino a me nā kemika maikaʻi, hoʻohana nui ʻia ia i ka ʻoihana, ke kūkulu ʻana, ka mahiʻai, ke ola o kēlā me kēia lā, ka pahu, ka uila, nā pono lehulehu, a me nā ʻano ʻē aʻe.ʻO nā resins PVC maʻamau he kūʻē kemika kiʻekiʻe.He ikaika loa a kū i ka wai a me ka abrasion.Hiki ke hana ʻia ka polyvinyl chloride resin (PVC) i nā huahana plastik like ʻole.ʻO ka PVC he mea maʻalahi, kūʻaiʻole, a pili i ke kaiapuni.

Nā hiʻohiʻona

ʻO PVC kekahi o nā resins thermoplastic i hoʻohana nui ʻia.Hiki ke hoʻohana ʻia e hana i nā huahana me ka paʻakikī kiʻekiʻe a me ka ikaika, e like me nā paipu a me nā mea pono, nā puka profiled, nā puka makani a me nā pepa paʻi.Hiki iā ia ke hana i nā huahana palupalu, e like me nā kiʻiʻoniʻoni, nā pepa, nā uwea uila a me nā kaula, nā papa papahele a me nā ʻili synthetic, me ka hoʻohui ʻana i nā plasticizers.

Nā ʻāpana

| Papa helu | QS-650 | S-700 | S-800 | S-1000 | QS-800F | QS-1000F | QS-1050P | |

| Degere polymerization maʻamau | 600-700 | 650-750 | 750-850 | 970-1070 | 600-700 | 950-1050 | 1000-1100 | |

| ʻIke ʻia, g/ml | 0.53-0.60 | 0.52-0.62 | 0.53-0.61 | 0.48-0.58 | 0.53-0.60 | ≥0.49 | 0.51-0.57 | |

| Maʻiʻo Volatile (wai i komo), %, ≤ | 0.4 | 0.30 | 0.20 | 0.30 | 0.40 | 0.3 | 0.3 | |

| Plasticizer absorption o 100g resin, g, ≥ | 15 | 14 | 16 | 20 | 15 | 24 | 21 | |

| VCM koena, mg/kg ≤ | 5 | 5 | 3 | 5 | 5 | 5 | 5 | |

| Nānā % | 0.025 mm mesh % ≤ | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.063m mesh % ≥ | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Helu maka i'a, No./400cm2, ≤ | 30 | 30 | 20 | 20 | 30 | 20 | 20 | |

| Ka helu o nā ʻāpana haumia, ʻAʻole, ≤ | 20 | 20 | 16 | 16 | 20 | 16 | 16 | |

| Keokeo (160ºC, 10 minuke ma hope), %, ≥ | 78 | 75 | 75 | 78 | 78 | 80 | 80 | |

| Nā noi | Nā Mea Hana Hoʻoheheʻe Injection, Pipes Materials, Calendering Materials, Rigid Foaming Profile, Building Sheet Extrusion Rigid Profile | Pepa Hapa-paa, Papa, Mea Papa, Linning Epidural, Nā ʻāpana o nā mea uila, Nā ʻāpana kaʻa. | ʻO ke kiʻiʻoniʻoni ʻoniʻoni, ʻeke, pahu pahu, nā keʻena a me nā papahele, nā mea pāʻani, nā ʻōmole a me nā ipu | Nā Pepa, nā ʻili hana, nā mea paipu, nā ʻaoʻao, nā bellows, nā paipu pale kelepona, nā kiʻiʻoniʻoni. | Na Mea Hookui, Uea Uila, Na Mea Uila, Na Kii Pahee a me na Papa | Nā Pepa, Nā Mea Hoʻolalelale, Nā Mea Hana Kalender Paipu, Nā Mea Hoʻohuihui o nā Uea a me nā Uea. | Paipu Waiwai, Paipu Wai inu, Paipu Pua, Paipu Sewer, Paipu Uea, Paipu Paa | |

Hoʻopili ʻia

(1) Hoʻopili: 25kg upena / ʻeke pp, a i ʻole ʻeke pepa kraft.

(2) Hoʻouka nui : 680Bags / 20′container, 17MT/20′container.

(3) Hoʻouka nui : 1120Bags / 40′container, 28MT/40′container.